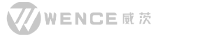

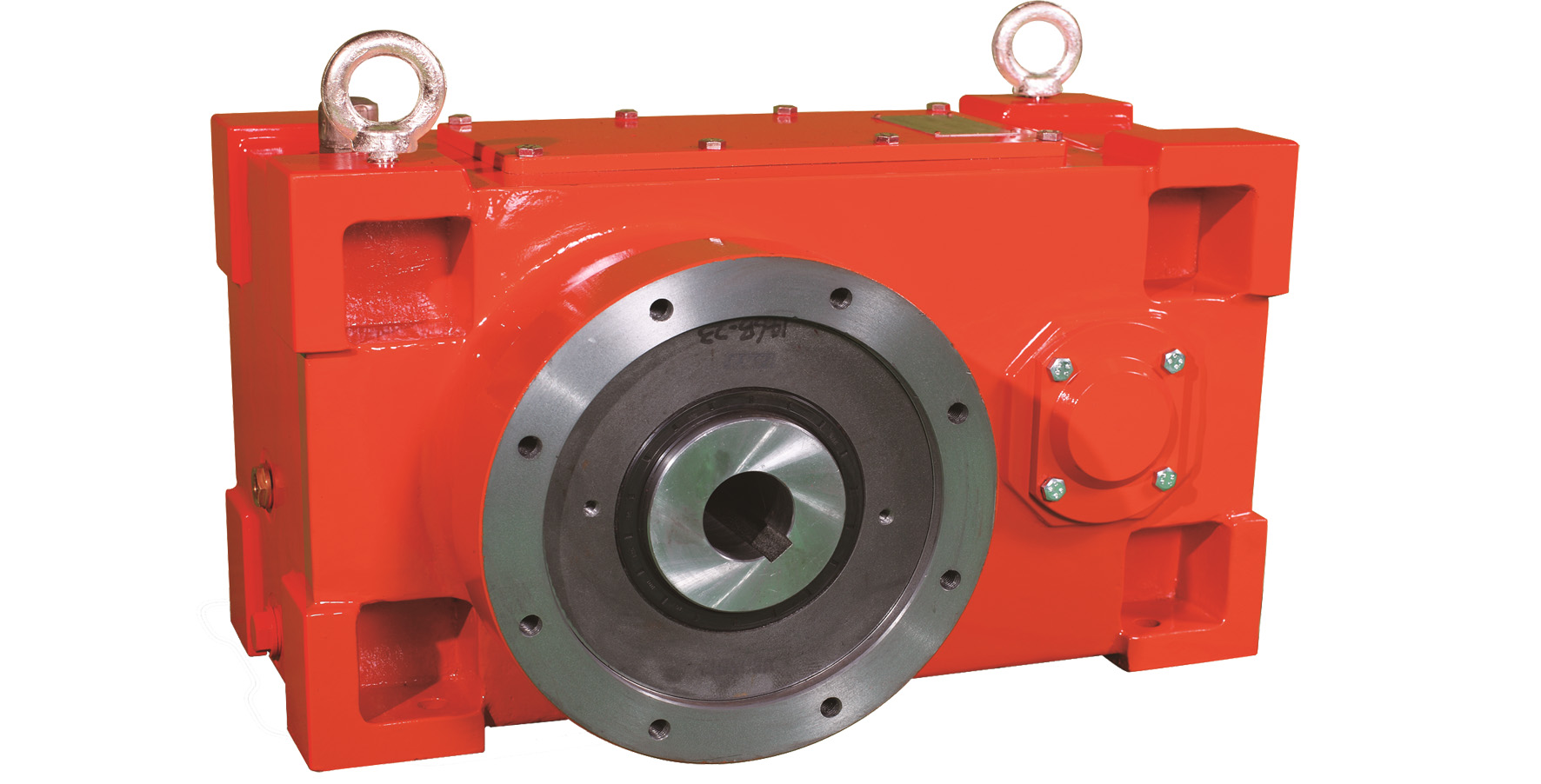

The reducer is generally used for the transmission equipment with low speed and large torque. The motor, internal combustion engine or other high-speed running power is used to reduce the speed by engaging the gear with a small number of teeth on the input shaft of the reducer with the large gear on the output shaft. The ordinary reducer also has several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio. The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a larger torque. Function of reducer 1) Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer. 2) At the same time, the inertia of the load is reduced to the square of the deceleration ratio. You can see that the general motor has an inertia value. Types of reducer Generally, there are helical gear reducers (including parallel shaft helical gear reducers, worm gear reducers, bevel gear reducers, etc.), planetary gear reducers, cycloidal pinwheel reducers, worm gear and worm reducers, planetary friction type mechanical stepless transmission, etc. Types of common reducers 1) The main feature of worm gear reducer is that it has reverse self-locking function and can have a large reduction ratio. The input shaft and output shaft are not on the same axis or plane. But the general volume is large, the transmission efficiency is not high, and the accuracy is not high. 2) The harmonic drive of harmonic reducer uses the elastic deformation controlled...

The reducer is generally used for the transmission equipment with low speed and large torque. The motor, internal combustion engine or other high-speed running power is used to reduce the speed by engaging the gear with a small number of teeth on the input shaft of the reducer with the large gear on the output shaft. The ordinary reducer also has several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio. The reducer is a kind of power transmission mechanism, which uses the speed converter of gear to reduce the rotation number of motor to the required rotation number and obtain a larger torque. Function of reducer 1) Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output deceleration ratio, but it shall not exceed the rated torque of the reducer. 2) At the same time, the inertia of the load is reduced to the square of the deceleration ratio. You can see that the general motor has an inertia value. Types of reducer Generally, there are helical gear reducers (including parallel shaft helical gear reducers, worm gear reducers, bevel gear reducers, etc.), planetary gear reducers, cycloidal pinwheel reducers, worm gear and worm reducers, planetary friction type mechanical stepless transmission, etc. Types of common reducers 1) The main feature of worm gear reducer is that it has reverse self-locking function and can have a large reduction ratio. The input shaft and output shaft are not on the same axis or plane. But the general volume is large, the transmission efficiency is not high, and the accuracy is not high. 2) The harmonic drive of harmonic reducer uses the elastic deformation controlled...

DC reducer, namely gear reducer, is based on the common DC motor, plus the matching gear reducer. The function of gearbox is to provide lower speed and larger torque. At the same time, different reduction ratio of gearbox can provide different speed and torque. This greatly improves the utilization rate of DC motor in the automation industry. Reducer motor refers to the integrated body of reducer and motor (motor). This kind of integration can also be called gear motor or gear motor. DC reducer has the characteristics of high transmission accuracy, small volume, low noise, durability, low energy consumption, long working life, etc.; the technical parameters of DC reducer manufactured and designed by Witz mechanical and Electrical Co., Ltd., with the diameter of 8mm-38mm; the gearbox material is divided into plastic gear and metal gear; the voltage is between 3v-24v; the transmission noise is below 45dB; the reduction ratio is 5-1500; The output speed is 5-2000rpm; the output torque is 1gf cm to 50kgf cm; the transmission accuracy is within 1-2 arc minutes. DC reducer, namely gear reducer, is based on the common DC motor, plus the matching gear reducer. The function of gearbox is to provide lower speed and larger torque. At the same time, different reduction ratio of gearbox can provide different speed and torque. This greatly improves the utilization rate of DC motor in the automation industry. Reducer motor refers to the integrated body of reducer and motor (motor). This kind of integration can also be called gear motor or gear motor. DC reducer has the characteristics of high transmission accuracy, small volume, low noise, durability, low energy consumption, long working life, etc.; the technical parameters of DC reducer manufactured and designed by Witz mechanical an...

In recent years, Chinas reducer industry has benefited from the continuous deepening of industrialization and urbanization process and the attention of the state to the machinery manufacturing industry. As one of the basic equipment industries in China, the reducer industry is one of them. After more than 40 years of market development, the reducer products have also developed from the original single cycloid reducer to the present gear reducer, worm reducer, etc., and are widely used in various fields of national economy, such as electric machinery, metallurgical machinery, environmental protection machinery, chemical machinery, food machinery, mining machinery, construction machinery, water conservancy machinery, etc., which are popular in the city Field favor. Reducer industry Driven by the national macro-control, Chinas reducer industry has gradually developed into the main battlefield of the international reducer industry. World famous enterprises have entered the reducer Market in China, and with the advantages of excellent brand, abundant capital, advanced technology and equipment, they have launched fierce competition with domestic reducer enterprises. However, domestic enterprises mainly engaged in the production of general purpose reducers have less involvement in the field of industrial special reducers and immature industrial technology. Therefore, in the competition with foreign advanced enterprises, if Chinas reducer industry wants to occupy the leading position in the market competition, it will take a long time for the market to hone. The slow recovery of the world economy makes the global consumer market active again. At the same time, the appearance of the effect of Chinas macroeconomic policies and the continuous strengthening of the investment in inf...

How to check and maintain the reducer effectively. Do not mix different lubricants. The position of the oil level plug, drain plug and breather is determined by the installation position. Their relevant positions can be determined by referring to the installation position diagram of the reducer. The following is mainly through oil replacement, oil level inspection, for the reducer with oil level plug, oil inspection and other aspects to elaborate. 1、 For reducers with oil level plug Check whether the oil level is qualified; install the oil level plug. 2、 Oil change It is difficult to drain oil when the viscosity of oil increases after cooling, so the reducer should change oil at operating temperature. Cut off the power and prevent electric shock! Wait until the reducer cools down and there is no danger of combustion! 3、 Precautions Inject new oil of the same brand; the oil volume shall be consistent with the installation position; check the oil level at the oil level plug; tighten the oil level plug and the ventilator; keep the reducer warm when changing the oil; place an oil pan under the oil drain plug; open the oil level plug, the ventilator and the oil drain plug; drain all the oil; install the oil drain plug. 4、 Inspection of oil level Cut off the power and prevent electric shock! Wait for the reducer to cool down; remove the oil level plug to check whether the oil is full; install the oil level plug. 5、 Oil inspection Cut off the power and prevent electric shock! Wait for the reducer to cool down; open the drain plug and take the oil sample; check the viscosity index of the oil; if the oil is obviously turbid, it is recommended to replace it as soon as possible. More information welcome to Nantong Shuanglu construction machinery factory. Welcome new and ...